As the internship comes to a close, we have been spending most of our time putting final touches on our device, analyzing the results of our comparative incubation test, and sharing our work. My teammates and I are so excited about the work we have been able to achieve, so it’s bittersweet to be so close to the end already.

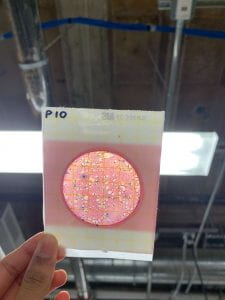

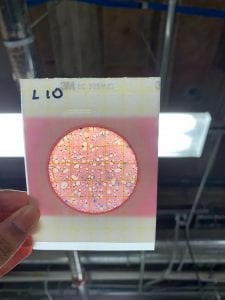

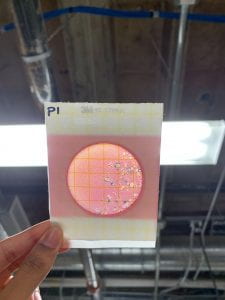

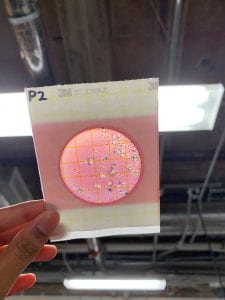

One of the most inspiring developments of the week that reinvigorated me for this final week was seeing our testing results: there was visually no difference between the 10 petrifilms we put in the commercial lab incubator and our own prototype. Ideally, we would have been able to numerically confirm this lack of difference, but according to Dr. Loyo (our mentor for this test), the bacteria were too far overgrown to accurately quantify.

Something interesting we noticed, however, was that the bottom 3-4 petrifilms in our prototype had a region where no bacteria grew. We hypothesized that this was likely because the heating pad did not lie perfectly flat in the wooden scaffolding– part of it was slightly crumpled and was touching the upper part of the scaffolding on top of which the petrifilms rest. Because of this contact, the wood there must have gotten too hot for viable bacterial growth and caused that area of the petrifilm to be partially or fully sterilized. The top 6-7 petrifilms were well shielded from this heat by the bottom 3-4 petrifilms, so they looked very similar to the commercial incubator petrifilms.

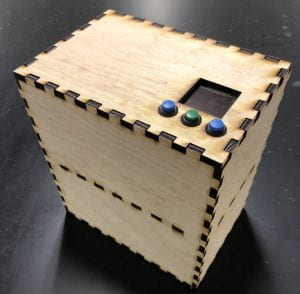

While we couldn’t quite get the perfboard ready for the Rice360 showcase on Tuesday, we had a really good presentation and demo with our breadboard circuit. We even got the circuit onto a smaller breadboard to fit completely into our device the day after the showcase! Not only did we get a lot of good input from attendees, but we also were reminded just how much we were able to accomplish in such a short timeframe. After the showcase, we spent time working on our journal article which will serve as a technical memo for Dr. Read (our client at Public Invention) and future teams working on our device.

Overall, I am so proud of my team and I for being able to achieve so much this summer. Personally, I can say I’ve learned a lot of new skills I hope to be able to use again 🙂

Teja Paturu