Hope everyone’s doing well! This week we finally finished organizing our files, presentation, poster, and presented our final project at the 2022 Internship Innovation Showcase! It was a very busy and a little stressful week, but it was all worth it once we presented our hand prototype and displaying it to our audience.

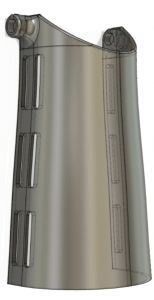

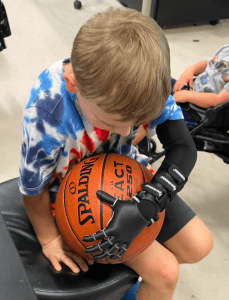

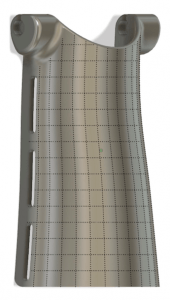

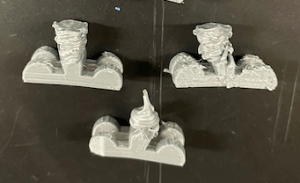

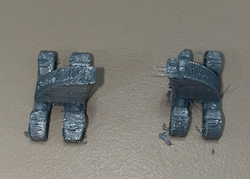

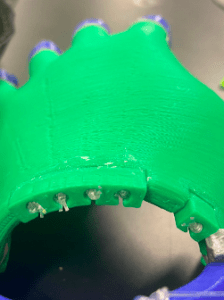

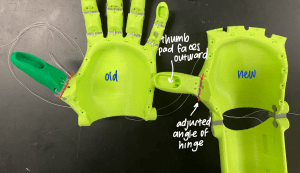

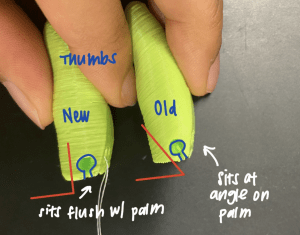

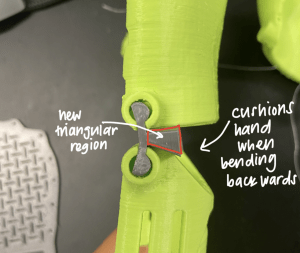

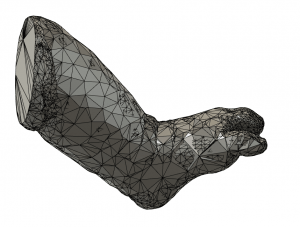

In our final prosthetic, we used higher-fidelity materials and printed the hand out of the nylon carbon 3D printer (MakerBot), making the prosthetic a lot more rigid, smooth, and durable for Eric Jr.’s needs. We also took some professional pictures of the final hand prosthetic to help with the presentation and display as seen below. At the end, we delivered our prosthetic to Eric Jr. and we were all really happy to see the impact all of our hard work made to Eric Jr. and his family!

Overall, this was a great summer experience and am glad I did it! I got to learn and practice many engineering skills such as using CAD, and gained more experience working with a team. We had multiple workshops to help us further understand the design process, and even got experience using the hand tools available at the OEDK. I enjoyed the networking lunches every Thursday at Cohen’s House, talking and learning so much from all the special guests I spoke with. I loved working on our project, having a single customer in mind and seeing first-hand the impact and joy our work brought to our client! I highly recommend taking this opportunity and doing this summer internships to any engineers and non-engineers who are interested in the engineering design process. I would like to give a massive thank you to everyone who made this internship possible, especially Dr. Taylor for helping me throughout the entire process!

I am extremely glad I did this internship and hope everyone enjoyed reading about my journey!

JJ Tellez

.

.