Third week of SEED is just wrapping up, and Team Toco is already making good progress on our design. We spent Monday doing more research, then moved on to define the design criteria for our project. In the afternoon, we started brainstorming possible solutions — to start off with, we mainly focused on getting the mechanical portion of the device to work so we can reliably send light through the fiber optic and measure it at the other end when we pull the wires apart. After doing our brainstorming, we ran our ideas through a Pugh matrix to help us sort out what to move forward with. We ended up with three possible solutions that we’re pursuing simultaneously for now. All of them involve housing the electronics of our device inside small plastic boxes and running the fiber optic between the boxes, which we’ll eventually 3D print. The major differences between our ideas involve what kind of elastic material will run between the two boxes: right now we’re thinking of using either sewing elastic, rubber strips, or a rubbery accordion-style material. We’ve ordered supplies for all of those, and we’ll start testing each of them out on Monday when they arrive.

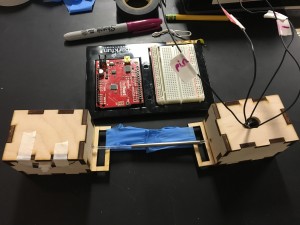

In the meantime, we’ve finished up a medium fidelity prototype of the design, using laser cut wooden boxes to house the electronics. For right now, we’ve got the LED attached to a 3V battery and taped to the fiber optic cable in one box, and a photoresistor and a small circuit hooked up to an Arduino kit in the other box (see the picture below). We can get light coming through the fiber optic really well with this setup, and we’re able to record it on the Arduino and see the changes in light level based on how far we pull the boxes apart. Now we’re working with our Arduino kits to learn some more code — we’re all going to take our kits home this weekend and try to get more comfortable working with them. We plan on starting to write some real code next week, starting off with trying to get the computer to just recognize when a contraction is occurring, and eventually working up to plotting the number and duration of contractions on some kind of display, and triggering an alarm when one of our three “danger” conditions is met.

Apart from working on the Optoco, we also spent some time this week learning to use a bunch of tools at the OEDK . We had a laser cutting workshop where we got to design our own lamps and laser cut them out of wood. Part of mine is pictured below — we should be staining/painting them next week sometime!