The week started off on Monday with early stages of the design process: research, setting design criteria, and brainstorming. Tuesday morning we researched a few more areas and then started our Pugh Scoring Matrix, however this was a bit of a difficult process for us. Since Dr. Carns already gave us the idea to use a fiber optic cable for our device, our brainstormed ideas were all variations on how we would attach it and what type of stretchy material we would use, which made estimating differences in how easy a design would be to apply or clean difficult to judge. Due to this, we didn’t finish before lunch and after lunch all of the interns participated in a “lamp making” workshop.

For the workshop, we partnered up and one person learned Adobe Illustrator and laser cutting while the other person, aka me, learned some Arduino and soldering. The kit that we soldered set LEDs to light up when the circuit detected noise, such as someone talking or clapping. I have had some experience soldering in the past with circuits I organized myself, so filling in a pre-marked circuit board wasn’t too difficult, which meant I finished with some extra time to go watch the laser cutting. That was the first time I’ve ever stood and watched a laser cutter work, so it was pretty snazzy. My partner, Jeremy, laser cut a box that would house the circuit I made, hence creating a “lamp.”

On Wednesday we finished our Pugh Scoring Matrix to determine our winning design. We had to order some materials for this, so in the meantime we started prototyping our runner up solution in case the materials for the winner don’t work out. Since Dr. Carns had provided us with a low fidelity prototype, we went straight for medium fidelity:

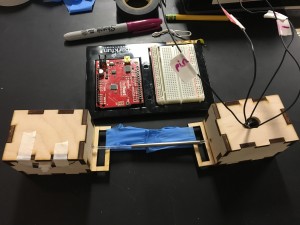

The prototype consists of two boxes with a piece of the fiber optic cable mounted to each. The slit of the fiber optic is covered by a piece of hypotube which is glued to one of the pieces of cable. In this photo, a piece of rubber glove connects the two boxes, although this will not be the final material. Inside one of the boxes a small LED is mounted against the fiber optic cable to shine through it and in the other box a photoresistor is mounted against the end of the cable and is a component of a circuit that hooks up to an Arduino kit such that we can read off light level values on the computer. After finishing this prototype on Thursday, we were able to begin thinking about the code that we will need to use in order to determine contractions, send warnings when the three conditions of possible impending uterine rupture occur, and ideally make a partograph like readout. As a result, today, Friday, we spent the morning learning Arduino, although I still feel very far away from being able to contribute to writing any sort of useful code. After lunch we made a graph of displacement versus light intensity with our prototype and found it to be exponentially decreasing, however we don’t know how sensitive the device needs to be such that it picks up contractions but not breaths. We tried to get a bit of an idea of how much breathing moves the stomach by measuring on our own stomachs, but our measurements were not particularly accurate.

Hopefully we will have materials arriving next week to work on our other idea while also starting to code our program, which will surely require baby steps.

Nathalie