Early Progress

Team Petri-FI began this week with a mission and a strong attitude. On Monday, we would get to see the previous Minicubator prototype, and later that afternoon we would meet with a member of the freshman design team, Moonrat, who would help us become familiar with his team’s project. On Monday, all of our documents and thoughts about the previous prototypes would merge with reality, and the long transfer of wisdom from the previous teams would begin.

Typically, every team faces roadblocks at some point in a project. Most of the time, they occur somewhere around the middle or the end, when disorganization lowers the threshold of bad luck. For our team, the roadblock was just a few days into our project, and only moments after we received the Minicubator prototype. First, we noticed some heat damage on the insulation layer, where the foam had expanded out of the confines of the incubator. The prototype was clearly not stored in its completed form, so some assembly was required to connect the battery, Arduino board, and the incubation chamber together. We plugged in the embedded heating pads and thermometer as best we could to the printed circuit board, plugged everything into the battery, and flipped the switch.

Magic smoke trailed out of the circuit board, and we could immediately smell the consequences.

While some of us were calm, others of us looked at each other, not knowing whether we had completely destroyed every last speck of the Minicubator prototype, or if we had merely damaged the Arduino or PCB. We quickly realized a potential point for a short to occur between our wires, so we applied liberal amounts of electrical tape and reconnected the battery. This time, the screen lit up with the current temperature and some incubation options! The heaters refused to turn on, and there was visible damage to the PCB, but we were somewhat relieved to see the Arduino powered on with a working interface.

Later that day, we met with an enthusiastic member of the Moonrat freshman design team (not Minicubator), who gave us incredible clarity when thinking about the potential for a thermos incubator design. Their previous design worked in a fairly large thermos, and it had some rough spots in the user experience. However, we were happy to know that this was an area in which our team could make considerable improvements, especially with the knowledge and progress that their team had already made.

Following the Process

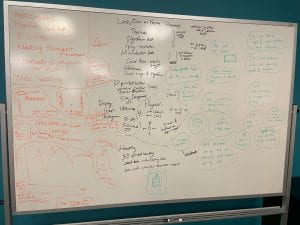

Throughout the week, we continued to attend workshops that highlighted the steps of the Engineering Design Process. Fantastic speakers helped us in areas such as defining design criteria, brainstorming, and objectively evaluating solution ideas. It was easy to get lost in the messy timeline of previous incubator projects, but returning to the design process gave our team a clear direction for moving forward. During the week, Team Petri-FI was able to define useful criteria and start brainstorming partial ideas for our design, all the while troubleshooting the technical problems we encountered earlier in the week.

A wonderful highlight of this week was “Morning Standup” at 10:30 each day. These were short discussion sessions with everyone from the internship. Here, each team has the floor to discuss their recent progress, express any challenges they’ve encountered, list their plans for the rest of the day, and ask questions to any other teams. This time is designed to allow teams to learn from each other as we make progress on our own projects, and offer help to each other. After a year of online classes and limited contact with other people, this type of interaction is incredibly satisfying. Whereas online classes and events create the impression that I am working on everything completely alone, morning standup allows me to see other people (in-person!) struggling and working through difficulties of their own. I am honestly getting emotional writing about this, because it means so much to be able to empathize with others, and receive sympathy when we endure our own challenges.

High Ground

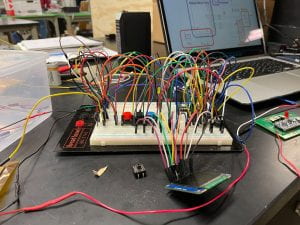

A fitting summary of this week would be “modeling.” We are still learning about the challenges of maintaining temperature in our chamber while keeping our battery small, so we designed a spreadsheet of electrical values and heat transfer parameters to help us estimate the power consumption of our incubator. We have used this to design small tests of different heating chambers, which will help us to evaluate some of our solutions and purchase an appropriate battery. When we struggled to test the previous Minicubator prototype, we grabbed a breadboard, and we followed the guidance of the team’s documentation to recreate the circuit ourselves, with wires galore. Since we haven’t been able to test code on the Arduino, I have had time to familiarize myself with the Minicubator code, add comments, and prepare to quickly test code when we get the system working again. Essentially, when we have encountered difficulties, we have spent time gaining the high ground on our problem. From research to brainstorming to breadboarding, we have prepared ourselves for the moment that we make a breakthrough.

The “magic smoke” incident may yet have been a blessing in disguise. It has encouraged us to take a more objective, distant approach to solving our problem. It has given us time to brainstorm improvements upon previous designs, and it has also forced us to learn more about the Arduino’s code and circuit board. Small adjustments to our team’s plans have guided us to a mindset of innovation rather than immediate construction. Ultimately, we are now in a much better position to make modifications to the circuit, battery, or components. Additionally, we are more than ready to perform heat transfer tests on multiple insulated chambers, once we get the breadboard working. During this internship, I hoped that I would gain some experience with electrical systems, and I have already learned so much from my teammates and other individuals. We are extremely fortunate to have the guidance of wonderful faculty and members of the Rice community who have helped us so far, and we are excited for our progress in the next few weeks.

-Kenton Roberts