This past week has definitely been a week full of twists and turns for team Heartache. Our team completed its first round of brainstorming based on the lung/heart motion component and the Saline box exterior component. We also met with our clients at the Texas Heart Institute (THI) Friday afternoon and from the Q/A we had with them pertaining to our device, we found that many of the solutions and mechanisms we had originally brainstormed were not aligned with some of the needs/expectations of our clients. As a result, our team initiated a second round of brainstorming the next week. We also spent some time prototyping these possible solutions

Our team also was able to finalize the design criteria, as shown in the list below:

- Cost

- Set-up (Measured by the amount of connection points between device and the Saline box apparatus)

- Maintenance

- Durability

- Accuracy of Motion

After our client meeting on Friday, we realized that tissue attachment was going to be reached using clamps, resulting in our team eliminating adjustability as a design objective. Using the ideas our team brainstormed for the different components, several holistic solutions were formed and put through the Pugh scoring matrix. As a result, our team came out with two solutions that we plan to go forward prototyping with. Descriptions of these solutions with pictures of their low-fidelity prototype are shown below:

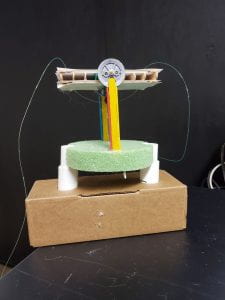

Solution 1: The tissue table where the tissue is clamped is built on a seesaw with strings being used to mimic the heart contraction using a rocking motion. The seesaw is built on a middle platform with one pole running through the center with strings being used again to this time create the vertical motion of the heart caused by the lung.

Solution 2: The tissue table is built on an axle with a string running through both ends of the platform to create the same rocking motion. The axle is built on a second platform that is also attached to a set of tracks where the vertical motion will be mimicked by strings once again.

This week was also marked by some interesting workshops pertaining to coding, 3D printing, and CAD. Luckily, our team was able to gain a clearer understanding of the design criteria before any major prototyping was completed, but this week has taught much about the importance of a design team constantly being on the same page with its clients.