This past week has been really great!

Closing out the third week, we had the opportunity to undergo a prototype evaluation by Dr. Wettergreen that gave us some constructive insights into our design and testing process moving forward. More specifically, Dr. Wettergreen highlighted that, as our final device would need to be submersed in saline, our early testing should be performed in saline to prevent eventual issues with our design. To illustrate this concept, he brought up the lesson of the spaghetti noddle-marshmallow challenge that he typically presents to his students. While I did not take ENGI120, I had the opportunity to participate in this challenge during my GLHT360 course. In this challenge, the students are tasked with building the tallest structure made solely from spaghetti noodles and tape that is able to support a single marshmallow. The trick to succeeding is to test early and often with the marshmallow rather than waiting until the very end. Based on this insight, we developed our next iteration in a manner that would allow for submersion in a saline solution.

The following day, after our midsummer presentations, we had another client interview during which we updated the THI team on our past week’s progress. The THI team liked our proposed solution’s track system that sought to facilitate the vertical (lung) motion and advised us away from the rocking motion. Instead, they suggested looking into creating a motion that was representative of a sine wave within a sine wave. In other words, have the heart motion be a sine wave of a particular frequency and amplitude while also having the lung motion be a sine wave of a particular frequency and amplitude. Once coupled, these sine waves would be able to represent the wanted cumulative heart and lung motion. With this new approach to the heart and lung motion in mind, we set about adjusting our prototypes.

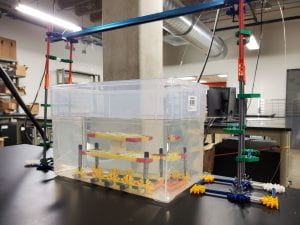

With this new direction in mind, we decided to explore two possible solution avenues: (i) a solution in which the combined heart and lung motion is instigated by a singular motor and (ii) a solution in which the motion is initiated by an iron solenoid (heart motion) and a motor (lung motion). Both of these solutions would, in theory, create the heart and lung motion mentioned by our clients. As a result of our pursuit of the two prototyping directions, we decided to split up different aspects of each solution among group members. Rachel worked on creating a functional prototype of solution (i) out of K’nex and PVC pipe (Figure 1) while also working on a higher fidelity version of the prototype that made use of 3D printed parts.

Figure 1: K’nex and PVC pipe version of solution (i)

Meanwhile, Sam and Chris further developed solution (ii) and started working on a functional model. At the same time, I continued to work on the Arduino code and circuits for both solutions. Currently, I have coded and built a circuit that allows the user to use a dial to vary the frequency of the servo motor’s sine waves (Figure 2) and see the set values of both the breath rate and heart rate on an LCD screen. Moving forward, I plan to work on coding the combined sine wave motion and also finalizing the code for the iron solenoids.

Figure 2: Our circuit setup, including servo motors, dials, and LCD screen.

Outside of our project work this past week, we also got to participate in some fun intern activities arranged by the TAs! This included a group scavenger hunt around campus which was a really great way to bond with other interns who are not on Team Heartache. My team ended up tying for first place!

Until next week!

– Kaitlyn Heintzelman