We’re halfway through the internship already! Week three has been a lot of fun as we developed and iterated through our very own art projects — initial low-fidelity prototypes. We’ve been continuously learning more and more about the intricacies of our project, from the scalability of materials to the quantitative analysis of ultraviolet light dosage.

When I started this internship as a remote intern, I didn’t think I would be a huge part of prototyping. My idea of developing prototypes was using 3D printers and complex laser cutters while configuring electrical circuitry. While these are important components of prototyping, prototyping consists of so so SO much more (I didn’t expect prototyping to be as artsy as it is!), and I feel as connected to the project as the rest of my team members do.

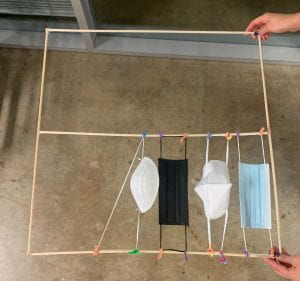

This week, I was able to learn the importance of low-fidelity prototyping, which so happens to be the first foundational step when engineering a new product. Our initial representational and ergonomic prototypes were an oil drum with a hanging framework attached to the lid, and a square box with a square framework that could be taken out of the box (peep the videos on last week’s blog!). Both of these prototypes have their pros and cons. On the one hand, the square box is much easier to produce and manufacture owing to its standard geometry. It is also easier to customize so that it fits our criteria and design needs. However, the oil drum, specifically chosen for its ease of accessibility in the settings we are designing for, can potentially allow us to produce at a large scale, despite having issues with usability and customizability.

To decide between our ideas, we met with international collaborators as well as the design coaches at Rice 360. After considerable deliberation, our team decided to go ahead with the oil drum idea. Despite the freedom a square or a novel shape may allow us, it would be useless if it could not be sustainably reproduced in a low-resource setting (or, worse, be imported from high-resource areas, only to end up in a graveyard of medical devices). With our overall structure finalized, we began work on designing the framework of UV bulbs and masks.

One of the hurdles of designing a framework is the exposure to UV light that the masks are allowed to receive. Too little exposure would mean the masks would not be sufficiently sterilized. Too much exposure might reduce the number of sterilization cycles masks can go through with their fit and structural integrity intact. After literature review on similar experiments, I found that a UV dosage of ~1.5 J/cm2 with the frameworks we are trying to engineer would ensure that the lowest dosage any part of the mask receives is 0.8 J/cm2 while the maximum is 3.0 J/cm2 (for reference 0.05 J/cm2 is usually enough to kill viruses and bacteria).

To end the week, we gave our mid-internship presentations. It presented a wonderful opportunity to learn more about the work everyone has been doing over the past few weeks. I was thrilled to learn about the feedback that everyone had to offer us! The occasion also presented a great opportunity for some team ~hybrid~ photos (see below). I’m excited for the second half of the internship!

— F