This week was a week of big strides! As the internship comes to a swift close, we are working on pulling together some final deliverables. We have a fully functioning circuit (minus a mysteriously buggy SD card), a more ergonomic casing, and an almost finished journal paper to pass on our work to the next team. The most exciting development, however, is that we are culturing a real water sample in our prototype.

After spending the beginning of the week troubleshooting our breadboard, Nancy began soldering together the circuit on perfboard. This will allow us to have all of the hardware far more compact than the scary rainbow tangle of wires we had on a big breadboard. Most importantly, this will allow us to fit all of the electronics into the small enclosure on top of our heating chamber.

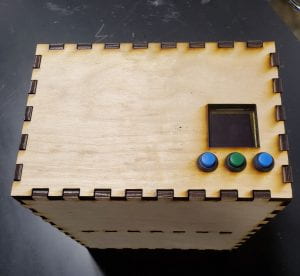

As a part of the next iteration of our plywood casing, we moved to arranging our electronics and heating chambers vertically on top of each other rather than side-by-side. We felt this orientation, though no smaller in size, makes our device more portable as it will now easily fit in a backpack in the correct orientation for the Petrifilms (they need to be held horizontally, parallel to the ground). Furthermore, we have cut holes out of the top surface of the electronic chamber for the buttons and screen to be displayed. Lastly, we implemented some intuitive doors for access to the SD card (which stores data), battery (to recharge after use), and also the Petrifilms themselves.

While we were working on the form factor and perfboarding, another teammate, Kenton, worked tirelessly on the code so that we could store temperature data for a test incubation period. However, the code simply would not read data to a file on the SD card. Even after a very knowledgeable mentor tried helping us, we just could not get data to transfer onto the SD card. However, because Kenton had biked all the way to Brays Bayou to collect water, we had to start an incubation cycle in our prototype as the individual bateria (which are what grow into visible colonies on our Petrifilms) would die after 24 hours.

To do our incubation test, we pipetted 1 mL of the Brays Bayou water sample to each of 20 different Petrifilms. We then placed 10 of these Petrifilms in our prototype and 10 in a commercial laboratory incubator. As of right now, the Petrifilms have been incubating for almost 24 hours. We will pull them out tomorrow (Friday, July 9) to see if colonies have grown- stay tuned for next week’s blog post to see our results!

Teja Paturu