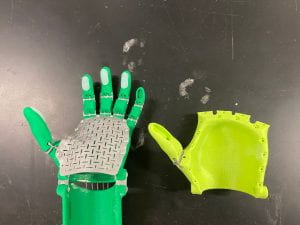

How’s everyone been? We just wrapped up with our 4th week and continued making edits to our prosthetic hand for Eric Jr. and brainstormed areas of improvement to our original prosthetic hand. This week flew by, however we were still able to get a lot of work done and gained a lot of experience with CAD. Rather than brainstorming completely new solutions or prosthetics for Eric Jr., our team decided it’d be more efficient to think about potentially flawed components in e-NABLE’s Kinetic Hand and brainstorm different alternatives to fix them. We decided to go with the Kinetic Hand because it was the simplest and most streamline design relative to the other 3D printable hands we found online. By the end of the week our team documented all the different components of our original hand that needed modifications and appropriate alternative solutions which would preserve the integrity of the original hand.

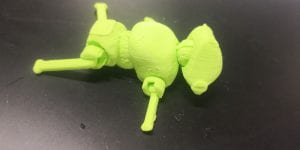

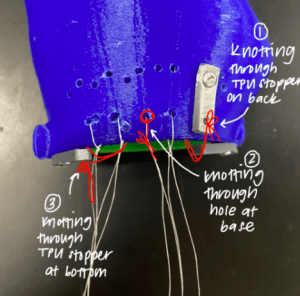

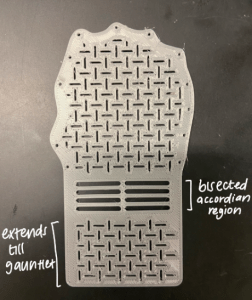

After brainstorming potential solutions to the flawed components of our original hand, our team quickly moved into the low-fidelity prototyping face to test the solutions we came up with. We first tested moving the string tensioners in the fingers to the bottom of the palm, drilling holes into one of our hands. Rather than editing and printing a new hand to include the holes at the bottom, our team decided it would be best to drill into an older prototype to quickly test our idea, able to quickly make a decision and move on. After quickly testing this idea, our team decided it was too complicated and considered even removing the strings to reduce complexity and maintenance of our prosthetic. Next week we will qualitatively test the additional support given by the strings and then will decide if it’s worth including them. We also wanted to increase support around the wrist and after brainstorming multiple ideas decided thicker wrist hinges would best solve our issue, proceeding to create and 3D print new modified wrist hinges. Finally we began editing the palm cover of the original device, as Eric Jr.’s small hand slips out of the current design. We thought it’s be best to extend the current cover all the way to the gauntlet of the hand, and create a pattern between both pieces to allow for wrist movement, however we are currently still working on which design to pick.

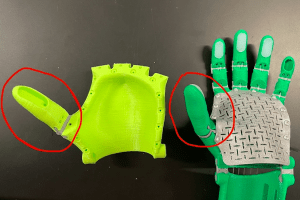

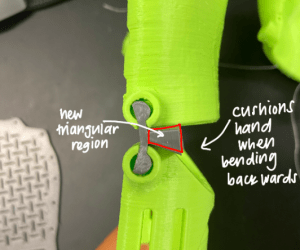

Again, this week we ran into a lot of challenges and failures, mainly during our low-prototyping face. We continued struggling with CAD this week, but after a lot of practice we began to see significant improvements and lots of new skills in Fusion360. Our team experienced the most failures so far this past week as we made low-fidelity prototypes to test our brainstormed ideas. The first failure happened while we tried to relocate our string tensioners to the bottom of the hand, as the string was not tight enough and would slip after being stretched. Another failure was extending the palm cover to the gauntlet, as the design we created between both pieces was not very flexible and did not allow for much wrist movement. Finally, while testing the durability of the prosthetic by passing and catching a basketball, the part connecting the palm and the thumb hinge broke off after attempting to catch an extremely hard pass. Even though it was a failure, it helped our team a lot because it helped us start brainstorming different ideas to reinforce that area sooner rather than later.

We are really excited to continue working on more modifications next week and have our final prototype for Eric Jr. done in the next few weeks! We didn’t get to see Eric Jr. this week, however we are really excited to go watch him play basketball in his YMCA league next weekend and cheer him on. We plan on handing him the first version of our hand prosthetic for him to use and practice at his game, and are really excited for him and his family to do all our progress since we last saw them. Even though this week had multiple failures, we had lots learning experiences and were able to quickly move on to improve our prosthetic.

See y’all next week!

JJ Tellez

Hip and Knee Model

Hip and Knee Model Shoulder Model

Shoulder Model Team Dinner

Team Dinner