Week Four: July 1st, 2015

Mikaela Juzswik

Hi, I’m completely on time with this blog post. Things have been incredibly busy down here, but in a great way—we’ve got a lot of traction now, and our team is really starting to take off! Design solutions ahoy!

Last week, in the not-so-extant wake of Tropical Storm Bill, Leah and I began brainstorming. In the spirit of engineering and brainstorming, we decided that no idea is truly too infeasible, dangerous, or utterly horrible to be considered unusable, so we got a lot of interesting ideas, for lack of a better word. These ideas include using pizza boxes to create a giant suctioning vortex, building a large freezer that would serve as a condenser, and an idea that I only described using the word ‘trees,’ whose significance (probably thankfully) been forgotten. Yes, most of these ideas were thought of during lunch, when we were sitting under trees, eating pizza, and using icepacks.

Far more important, however, is the great news—in the process of generating some truly terrifying ideas, Leah and I found a bunch of promising gems.

In the past week, we’ve mostly been focusing on ways to generate pressure—the breast pump, naturally must provide suction, but we also need ways for it to release that pressure. In other words, lactation is not caused by constant suction on the breasts; rather, the suction simulates the suckling of the baby, causing the milk to be expressed. Devices such as bike pumps only have one direction of airflow, so we had to expand our horizons a bit. Methods of generating pressure (and applied in strange ways) included squirtbottles, mechanical bellows, syringes, various household objects such as bottles used as diaphragms, nesting objects with springs, peristaltic pumps, and re-invented aquarium pumps.

We also began to foray into ways to optimize user comfort. Previous complains about mechanical breast pumps suggest that they’re too tiring on the hands—after all, they entail repeating the same crimping motion thirty to sixty times per minute for thirty minutes. We tried to incorporate more natural body motions into our design, such as riding a bicycle, using a foot pedal, sitting in a rocking chair, and even shifting body weight.

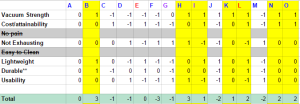

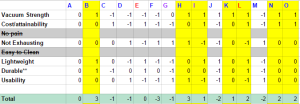

In total, we generated about thirty unique ideas, which we began narrowing down using screening and scoring matrices, tools used to decide which ideas are optimized based on a set of internal design criteria. The screening matrix proved easier said than done, and we got a little delayed from our weekly goals of selecting a prototype to design. Initially, the final optimal designs that we received from our scoring matrix didn’t match up with our vision of the project—in other words, ideas that we thought were fairly good weren’t scoring very well on the matrix, while ideas that we didn’t prefer were receiving markedly higher scores.

[pictured above: the culprit, condensed for your viewing pleasure]

After speaking with Dr. Wettergreen, we found that we needed to reconsider our weighting for the design criteria: a lot of the issue was rooted in the fact that our weightings caused the matrix to score low-cost designs much higher than high-comfort designs, allowing cheap designs that could be potentially dangerously uncomfortable to rise to the top. After re-weighting our criteria on Friday, we looked forward to having a much more promising crop of results from our scoring and screening matrices.

In other news, Harrison and I put the finishing touches on the Intubox! The whole thing looks quite solid, and I ended up taking a hit for the team when we needed to determine the attaching power of industrial-strength superglue.

Turns out it can support a hammer attached to a human finger. The good news was this indicated that the glue would be of sufficient strength to attach key components of our box (such as feet and magnets); the bad news was this indicated that I’d accidentally glued a hammer to my hand.