The past two weeks have focused on improving our APGAR device and getting acquainted with Incubaby.

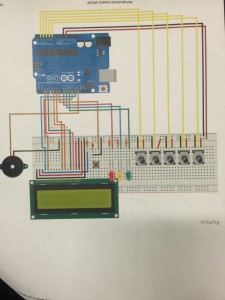

After several laser-cut prototypes for our electronic APGAR scoring device, we found a format we liked. It includes three LEDs to indicate the state of the baby, a buzzer at 1 and 5 minutes to remind nurses to record APGAR scores, and an LED screen displaying the timer and score. The score be changed with 5 sliding potentiometers that range from 0-2. Below are pictures of the device in action and the wiring diagram.

We’ve sent the device along with our clip prototypes to Malawi with Dr. Wettergreen and hope to the receive feedback soon.

We’ve begun to work on Incubaby as well. Currently, the design allows for a buildup of carbon dioxide from the baby’s respiration. We have used SolidWorks and the laser cutter to create side panels with circular holes that can be plugged and unplugged with PVC pipe and duct tape (below). This has allowed us to test different permutations of ventilation holes.

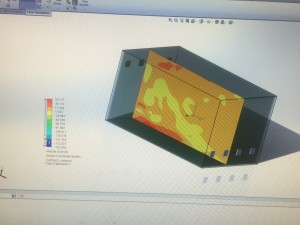

I have also spent some time modeling the air flow in the incubator using SolidWorks Flow Simulation 2013. The program allowed me to see how the air flow patterns work and how hole placement impacts the velocity and outlet flow of air. Below is a picture of the box cross-section representing velocity in the X direction and a video of the air flow trajectories.

Our solutions for ventilation reduced CO2 levels to an acceptable limit, however they allowed for too much heat loss in the box.

Next week we hope to cut and build an entirely new Incubaby with features that allow for heat retention.