It’s hard to believe that 3 weeks of SEED are already over; we’re almost halfway done with the internship! The thought brings mixed feelings to my mind.

For one, this means that the international students from Malawi and Brazil who I have become good friends will be leaving soon. I’m certainly going to miss them afterwards but I’m we’ll stay in touch. And of course, that only means that we’ll make the most out of the remaining month.

I’m also starting to realize that we only have 4 weeks left to finish prototyping and working on our project. Although our progress is good, the thought is still surprising and motivates me to maintain our team’s momentum and finish strong. This was the first full week where we worked on the forearm rotation device and prototyping is coming along well.

Our team decided to take a modified approach to the engineering design process. Conventionally, the design team will brainstorm ideas, screen/score them, and then start prototyping their main design solution. However, our team instead brainstormed ideas and jumped straight to low-medium fidelity rapid prototyping. With the help of 3D printing, we can easily fabricate our ideas. Once we have functional prototypes for all of our brainstormed ideas, we plan on revisiting the scoring process and using physical testing to base our decisions. This route was suggested by Dr. Wettergreen and is more suitable since we are working off an old design and our brainstormed modifications are too minute to be easily screened using the conventional method.

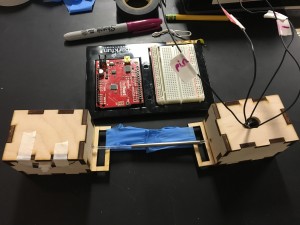

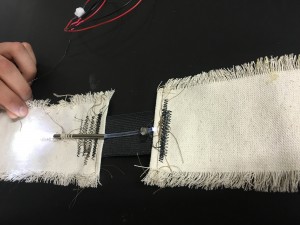

The 3D printer allowed us to easily recreate the old team’s prototype, shown here.

After the brainstorming and initial screening process, we have found 3 main ideas we want to work with. An exterior tab sliding on rails, and interior tab sliding within rails, and concentric rings sliding on an inner tube. Each one of these ideas maintains the original team’s shell for measuring forearm rotation but modifies the geometry of the technique. Our goal is to reliably reduce friction in this design block, while also maintaining an accurate and durable device.

Next week, we will put together our ring design ideas, test/score them, and finally pick one design to move forward with. This will allow us to move on to the wrist and elbow attachment mechanisms, our other two design blocks.