Two weeks have passed and we have now completed the first phase of the internship, prototype evaluation! Through our work this week, my team and I have started to make progress on our technology projects and deepen our understanding of engineering design. Our first group meeting was with Dr. Matthew Wettergreen from Rice University and, having worked with him before on a previous global health technology, I was excited for the input and expertise he would bring regarding the engineering design process and materials and manufacturing. During the workshop, my teammate Chikumbutso and I presented the problem context, identified customer needs, and our newly created design criteria for his feedback and incorporation into the activities in the workshop. The greatest thing I took away from our conversation was FFF – Focus on Function First. Essentially this means that, shockingly, the goal in prototyping is not to solve the problem; rather, its purpose is to gain enough momentum so that you can solve the problem. Given the time constraints and focus of the internship, this new phrase has greatly helped my team align our goals and gain perspective on our two COVID-19 problems. We learned a second vital engineering design tool from Dr. Wettergreen called “I like, I wish”. With this method, you say one thing you like about the design and one thing you wish it could have. For example, with the intubation box, many of our colleagues liked that the prototype was simple in design and manufacturing, but they wished that the physician could be in a more comfortable position during intubation. We also had the opportunity to do an in-depth evaluation of each of our prototypes that allowed my team to gain a better understanding of how each aspect of the devices was progressing.

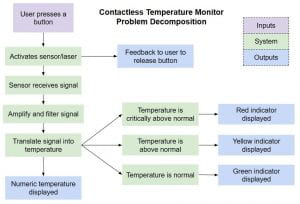

The following day we worked with Phil Repsiky from Torc Robotics, a company that specializes in autonomous vehicle technology, to decompose our problems into their basic functions and components. Through this process, I was able to learn how contactless temperature monitors and IR sensors work, and we realized some key functions we thought could benefit the device, including a feedback mechanism that alerts the user to release the button once the temperature is taken.

On Thursday my team and I did our first group brainstorming session in which we each took 10 minutes to write and draw out as many ideas as possible for our two prototypes. For the intubation box, I focused on two main factors – physician ergonomics and droplet reduction. The current prototype requires the physician to be in a hunched-over position that complicates the intubation procedure and puts an excess strain on the physicians back. To mitigate this issue, I proposed a slanted front panel for the box to help with visualization. To address droplet reduction, I thought we could develop a more effective method for decreasing particles exiting the patient-end of the box, such as Velcro strips/button fasteners and a reusable sheet to cut down waste.

For the contactless temperature monitor I chose to focus on brainstorming ideas for usability and shape rather than specifics for the electronic components. For example, I proposed the monitor could be shaped like common household items that are hand-held, such as a TV remote or water hose attachment, so that they are intuitive, simple to hold, and easy to use. Through the brainstorming process, my team and I learned of basic functions that needed further research and we centered ourselves on the scope of the projects.

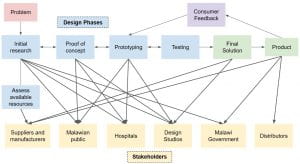

Our final workshop of the week was with Dr. Gobin where we explored the roles of various levels of stakeholders and developed stakeholder maps that helped us determine which contributors and resources would be beneficial at each phase of the design process. After completion, each of my team members and I discussed things we took away from our discussions to gain the bigger picture and overall meaning of the activity. My main takeaway from observing our map was how vital our primary stakeholders are (such as the Malawi design studios, hospitals, and the general public) in the beginning phases of the design process we are currently in and how important it is for us to continually cycle throughout the flow of the map.

The workshops this week were the most interactive yet, and each two hours session was completely filled with activities and back and forth discussions that helped us not only further develop our technology projects, but also taught us engineering design and global health tools and concepts for us to take with us into future work. Based on how productive my team was this week and the significant progress we have made, I can’t wait to see where we are at the end of the internship in four weeks!

See you next time,

Lauren