If you’ve ever been around me when I play music in the OEDK, you’ll know that the very first question I always ask is “What should I play?” I’ve always struggled with making everyday decisions–what snack to eat (something healthy? crunchy? or just…chocolate?), what clothes to wear (sometimes I’ll go through 4 outfits each morning), or even something as simple as what music to play (being the OEDK Basement DJ is stressful!).

This indecisiveness came into play this past week as we were finalizing our project design. As mentioned in the previous blog post, we have been back and forth between two design geometries: a cylinder shape (Carl) and rectangular shape (Geraldine/Gertrude). However, after weighing the pros and cons of the two designs, we found ourselves stuck in the decision of which one to pick.

On one hand, the cylindrical shape would be made from a 55-gallon oil drum, which is both a standard shape and size and is very common in our African partners’ countries. It would not require any manufacturing or coating processes to make the actual enclosure, being made from a UVC-resistant metal. However, the design process would prove complicated: limited space for the bulbs/masks, and limited space through which to remove the frame.

On the other hand, a rectangular shape would need to be manufactured from sheet metal or UV-protectant-treated wood, both of which require decent time and effort to manufacture. However, the scaleability of the design and ability to open the side of the box and simply remove the mask trays would mean greater usability and ease of design.

So now you can see our dilemma! We were set up to make a choice between Carl’s accessibility and ease of manufacturing versus Geraldine/Gertrude’s ease of use and design. Luckily for my indecisive self, Dr. Matthew Wettergreen visited to discuss our prototypes. When we showed him our lo-fi prototypes, it took him all of 5 seconds to matter-of-factly state, “Forget the box ideas–let’s focus on the barrel.”

Well…that was easy. If that’s how normal people make decisions, I could definitely use some of that surety.

After discussing the advantages of this choice as a team and with Dr. Andi Gobin (one of our clients), it was decided: we were moving forward with the oil drum design.

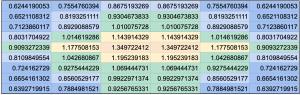

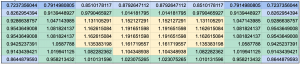

If only we could have stopped the tough decisions there! When designing the frame, we had to choose between a triangular prism shape which used 8 bulbs but disinfected 27 masks per cycle, and a single rectangular mask frame which used 6 bulbs but disinfected 15 masks per cycle. Abby and I made countless UV exposure estimations, spending hours calculating the UV flux at different points of the frame. I’ll include a screenshot of our calculations below: green indicates ideal exposure levels, while yellow/orange are too high and blue is too low. Our goal was to minimize the disparity between the highest and lowest points of exposure on the frame.

Above: Exposure calculations for the 8-bulb triangular prism orientation in the oil drum (dosage disparity: 0.73). Below: Exposure calculations for the 6-bulb single tray orientation in the oil drum (dosage disparity: 0.47) . Measurements are in J/cm^2.

Unfortunately, all of this work only proved that the two frame ideas provided awfully similar exposure results. Stumped, we then estimated how many masks would fit in each design. Although the triangle could fit more masks per unit time, the three of us decided that ease of use trumped the slight increase in efficiency and were able to make a big design decision on our own!

Long story short, I am learning the value of balancing the need for data-based decisions with the practicality of gut instinct in order to effectively make decisions. Let’s see if tomorrow, I can take less than 15 minutes to decide what I’m going to wear!