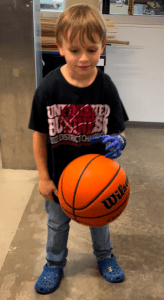

Hi everyone! After meeting with Eric Jr. and Arinze, president of Rice’s e-NABLE chapter, last week, our team quickly got to work. We decided that e-NABLE’s Kinetic Hand model was the most appropriate for our project, and began printing multiple different sizes for Eric Jr. to try out. During this process, our team learned about the different types of filaments the 3D printers can use, which change the properties of the final product. The most common filament is PLA, which is the typical plastic material most people think of when using a 3D printer. However, we also tested and used TPU, a more elastic filament which allows for a more flexible final product, and NinjaFlex, which is even more elastic. Our team tested printing out the wedges and palm cover using TPU and NinjaFlex filament, trying to see which filament would be best suited for Eric Jr. By the end of the week, our team was able to print out 3 differently sized Kinetic Hands for Eric Jr. to test out on Friday, using PLA (blue and green), TPU (gray), and NinjaFlex (light green) to see the properties of each filament.

Furthermore, our team also started and finished documenting our design criteria. After much discussion, our team came up with the following design criteria: Basketball Maneuvering, Durability, Comfort, Maintenance, Ease of Use, and Aesthetics. After clearly defining each design criteria, our team proceeded to do a piece-wise comparison chart and ranked each design criteria from most to least significant, in the order listed above. Finally, our team discussed different ways in which we could quantify and score each design criteria, going from a qualitative to a more quantitative approach by using user defined scales and potentially likert scales.

Even though our team progressed a lot and had several successes, we also experienced some failures here and there. For starters, the cast we got last week from Eric Jr. was unsuccessful, as the consistency of the plaster was too moist and the cast did not include his forearm. Our team took some time to better understand the casting process and conducted more test trials to refine this process. Also, one of our first attempts to print a Kinetic Hand model drastically failed, as the 3D printer malfunctioned and printed out a huge blob of plastic. Finally, it took some time and adjusting when working with both elastic filaments, TPU and NinjaFlex, as they were a lot more sensitive than PLA and would fail more often.

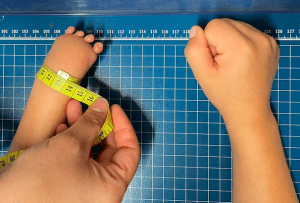

Despite these failures, our team made great progress in our project and our really excited about what’s to come in the following weeks. On Friday we were able to meet again with Eric Jr. and showed him all the hands we printed for him to test out and give us feedback. Once again, seeing Eric Jr. and getting to interact with him was the best part of the week, able to see the impact our project is having in his life. Eric Jr. had a lot of energy when he got to the OEDK with his dad and siblings, dribbling the basketball every second he could. While they were at the OEDK, we were able to recast his small hand and take accurate measurements of his wrist and forearm for future prototyping, as well as received helpful feedback on usability and comfort of our current prosthetic hand. I even got to play a 1v1 against Eric Jr. in the OEDK which was a lot of fun, seeing his passion for the game and his skills despite his disability. I am super excited to continue working on our prosthetic hand and finalizing our device over the next couple of weeks to help improve Eric Jr.’s basketball skills!

See y’all next week!

JJ Tellez