Hi everyone! It is hard to wrap my head around the fact that Week 5 of the internship has already ended. I think it is fascinating to think about how time has been flying by recently compared to when we were still in the brainstorming/planning phase. While it is scary that time is moving by so fast when we really need more of it, I also find it exciting to see our design take shape!

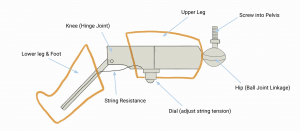

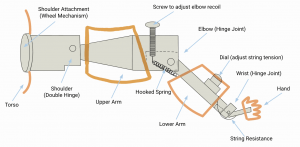

My team and I began the week by actually taking a step back and sketching out our design. We realized that, while we had a great conceptualized understanding of our prototype design in our heads, we were having some trouble communicating ideas about our project to our mentors and to people who weren’t as familiar with our project. Drawing out the individual limbs and the mechanisms associated with each joint was an effective way to close those gaps, and it was also a great way to make sure we were all on the same page in terms of the actual mechanisms.

Figure 1. Leg Sketch Figure 2. Arm Sketch

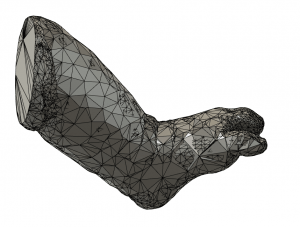

Once we solidified our foundation, we were able to look into ways to make our models physiologically realistic. We initially looked into molding our limb parts and inserting them into our 3-D printed bone structure, but the process was very messy and very expensive as well. We then looked into 3-D scanning. The process includes placing our parts on a rotating platform. The scanner then takes pictures of the part at different orientations, and it then meshes these scans together to create the final 3-D scan. Even though I saw it all happen in real-time, it was still really hard to wrap my mind around the idea of a machine technologically capable enough to create such an accurate 3-D model. We then incorporated the 3-D scans with the existing bone structure through the 3-D printing software, and we were able to fully integrate everything! After so many weeks of playing around with mini models of the bone structure, it was really exciting to see a full version of the leg with everything incorporated. There is still a lot of fine-tuning to do, but this was a huge step in the right direction.

Figure 3. Lower Leg 3-D Scan Figure 4. 3-D Printed Leg

Besides working on the physical design of our training model, we also created a pitch presentation for the design showcase next week. Not only was I able to work on crafting aesthetically pleasing and effective slides, but I was also able to practice learning how to distill our project context and design into higher-level summaries. The feedback that we received from our mentors opened our eyes to different aspects of information organization, and it also encouraged me to think about how the information we are presenting would be received by people who are not familiar with the design process.

While week 5 definitely had its challenges, we made a lot of great progress in terms of our design and presentation. The limited amount of time that we have has been tough, but I am confident that we will be able to continue making good progress!

See you next time, Lam Nguyen

.

.