When I was 8, my dad convinced me to go on the Steel Eel roller coaster at SeaWorld. I hated scary rides at the time, but the trip up to the top of the first drop was beautiful. All I kept thinking was, how far up can we go?

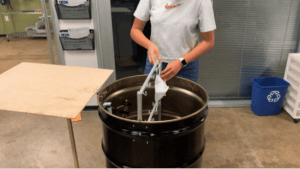

The beginning of this week was a lot like that first ride up on the Steel Eel. Once our oil drum (Ollie) came in, we were overjoyed to begin work on our high fidelity prototype. We even had some of the interns climb in and take a picture (me included, of course :))

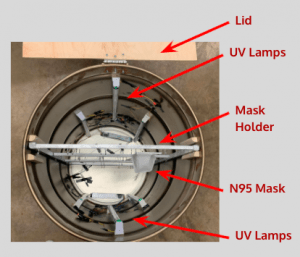

We were also thrilled to find that Curtis (our mask frame) fit within the drum. Once we sanded down the sides and shaved a centimeter off of the middle dowels to shrink the width, the frame was easy to place and remove within Ollie!

For a track system, we cut and sanded the 0.75” dowels to create a narrow window through which the frame could slide. This would ensure that the frame stays an equal distance from both sides of the drum and the masks would get even exposure.

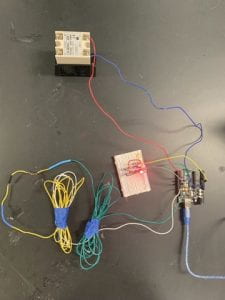

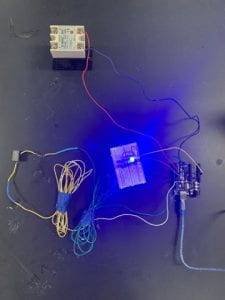

Next, we tackled the circuit that we had removed from the previous Steribox prototype! With the help of Christian (one of our TAs), we debugged the Arduino code and set up our breadboard so that our LEDs would be linked to the reed (magnetic) switch! I’ve attached pictures below: red indicates that the lid has been opened before the cycle has finished (this prevents harmful exposure to UV light), and blue indicates that the UV lights are running. Once the cycle has finished, both lights turn off.

We were extremely excited heading into Thursday afternoon–our circuit was working, our oil drum was set up; all we needed to do was plug in the bulbs and we could start testing. However, when we showed our circuit to Joe Bailey (Rice 360˙ Chief Electronics Designer), he pointed out several serious safety issues, such as exposed wires and unstable connections. In that moment, it seemed that plugging in the oil drum was not going to happen.

Naturally, this is where we reached the top of the Steel Eel and began to plummet down the first drop. We sadly adjusted our scope to account for the inability to do any UV testing as originally planned. In fact, it didn’t seem like we would be able to accomplish our ultimate goal: to get a working prototype at the end of the project.

However, the roller coaster began its next uphill descent when Joe pointed out some safety measures that could make our circuit usable. Abby and I dashed to Home Depot and found fluorescent bulbs with the exact same wattage and size as our UV bulbs. We were hopeful that at the very least, we could plug in the drum and show that if it worked with fluorescent lights, it would do the same with UV lights. Sure enough, by the end of the week, we were able to get the fluorescent bulbs plugged in for long enough to take a demo video.

Although we had a scare with our circuit, we learned to always ensure safety before plowing ahead with testing. Hopefully, we will be able to stay on an upward trend as we near the end of the internship…but knowing the Steel Eel, we will be prepared in case we go down another drop.